Facility location decision in logistics management

Facility location decisions are long term decisions taken for business growth, profits and success. The globalization of markets and businesses has necessitated manufacturing plants and distribution networks globally (Khumawala and Kadipasaoglu, 2006). Businesses in order to increase their market share and gain a competitive edge regularly take decisions regarding facility locations. It refers to:

- Where they should be located?

- How many centers to be established?

- Finding an efficient distribution network?

Importance of facility location while designing a logistics network

The location of new facilities is an important decision in logistics management. It includes retailers, warehouses and factories. This decision determines the efficiency of the flow of goods in the distribution system. Another reason for a business to decide the facility location is limited to the storage capacity of warehouses. Limited capacity impacts the cost of transportation of goods. Therefore, it is important for businesses to make informed decisions about distribution centers (Bramel et al., 1997). It is also important to take into consideration spatially distributed customers and the facilities required to meet their demands with minimal costs and time (Melo, Nickel, and Saldanha-da-Gama, 2009). Facility location planning facilitates businesses to get equipped with resources to handle unforeseen events such as natural and man-made disasters (Melo, Nickel, and Saldanha-da-Gama, 2009).

Creating a distribution network

The distribution network moves a product from the supplier to the customer in the supply chain. It directly impacts supply chain cost and customer experience. Structure of distribution network influences response time, product variety, product availability, customer experience, order visibility and returnability (Chopra, 2003). Response time here implies the time span between the customer placing the order and the delivery.

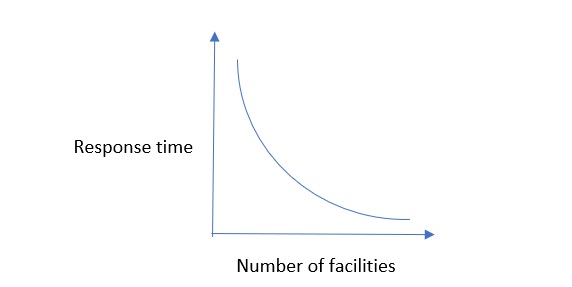

Furthermore, there is an inverse relationship between response time and the number of facilities required by a customer. As shown in the figure below, the number of facilities decreases with the increase in response time. Response time is different for different products.

For example, Amazon considers the response time of a book buyer can be higher than that of a phone buyer. Therefore, Amazon delivers books with higher response time and a phone with a slower response time. This helps Amazon manage the warehouse’s capacity efficiently between books and phones. This is in contrast with the offline retailers store a smaller variety of books in their limited warehouse space and have a low response time (Demir and Page, 2017).

Facility location decision depends on several factors such as:

- Product variety,

- transportation cost,

- and customer response time and many other factors help the firm to determine the form (Fleischmann et al., 2000).

Location techniques that help the decision-making process

To find an appropriate location for operations, expansion or relocation analytical hierarchy process (AHP) developed by Thomas Saaty in 1980 can be used. Here, decisions are taken according to the hierarchy of objectives. The AHP model has been further modified to suit the changing dynamics of the consumer market. It determines rank in the logistic center location (Alberto, 2000). Furthermore, it involves both tangible and intangible factors such as customer satisfaction, intuitive, rational, quantitative and qualitative aspects. It requires a logical and rational control of decisions.

Another methodology used is Axiomatic Fuzzy Set (AFS) to evaluate the logistics center location. The Technique for Order Preference by Similarity to Ideal Solution (TOPSSIS) which is based on the final selection. This is developed using modern principles of town planning and logistics (Li, Liu and Chen, 2011).

References

- Alberto, P. (2000) ‘The Logistics of Industrial Location Decisions: An Application of the Analytic Hierarchy Process Methodology’, International Journal of Logistics Research and Applications, 3(3), pp. 273–289. doi: 10.1080/713682767.

- Bowersox, D. and Morash, E. (1877) ‘The Integration of Marketing Flows in Channels of Distribution’, European Journal of Marketing, 23(2), pp. 58–67.

- Bramel, J. et al. (1997) ‘Facility Location Models’, in The Logic of Logistics. doi: 10.1007/978-1-4684-9309-2_12.

- Chen, Y. and Qu, L. (2006) ‘Evaluating the selection of logistics centre Location using fuzzy MCDM model based on entropy weight’, Proceedings of the World Congress on Intelligent Control and Automation (WCICA), 2, pp. 7128–7132. doi: 10.1109/WCICA.2006.1714468.

- Chopra, S. (2003) ‘Designing the distribution network in a supply chain’, Transportation Research Part E: Logistics and Transportation Review, 39(2), pp. 123–140. doi: 10.1016/S1366-5545(02)00044-3.

- Demir, M. A. and Page, | (2017) Management Information System: Case Study of Amazon.Com, Quest Journals Journal of Research in Business and Management.

- Fleischmann, M. et al. (2000) ‘A characterisation of logistics networks for product recovery’, Omega, 28(6), pp. 653–666. doi: 10.1016/S0305-0483(00)00022-0.

- Haniefudin, Shamshuddin, S. and Baba, S. K. (2013) Essentials of logistics and Supply Chain Management.

- Hong, J. (2007) ‘Firm-specific effects on location decisions of foreign direct investment in China’s logistics industry’, Regional Studies, 41(5), pp. 673–683. doi: 10.1080/00343400601120304.

- Khumawala, B. M. and Kadipasaoglu, S. N. (2006) ‘FACILITIES LOCATION DECISIONS’, in Encyclopedia of Production and Manufacturing Management. doi: 10.1007/1-4020-0612-8_316.

- Li, Y., Liu, X. and Chen, Y. (2011) ‘Selection of logistics center location using Axiomatic Fuzzy Set and TOPSIS methodology in logistics management’, Expert Systems with Applications, 38(6), pp. 7901–7908. doi: 10.1016/j.eswa.2010.12.161.

- MacCarthy, B. L. and Atthirawong, W. (2003) ‘Factors affecting location decisions in international operations – A Delphi study’, International Journal of Operations and Production Management, 23(7–8), pp. 794–818. doi: 10.1108/01443570310481568.

- Melo, M. T., Nickel, S. and Saldanha-da-Gama, F. (2009) ‘Facility location and supply chain management – A review’, European Journal of Operational Research. Elsevier B.V., 196(2), pp. 401–412. doi: 10.1016/j.ejor.2008.05.007.

- Rushton, A., Croucher, P. and Baker, P. (2006) ‘The handbook of logistics and distribution management’, Project Management Journal. doi: 10.1371/journal.pone.0030504.

Discuss